Efficient Hnub Ci Vaj Huam Sib Luag Interconnect Ribbon rau Enhanced Energy Connectivity

Kev piav qhia

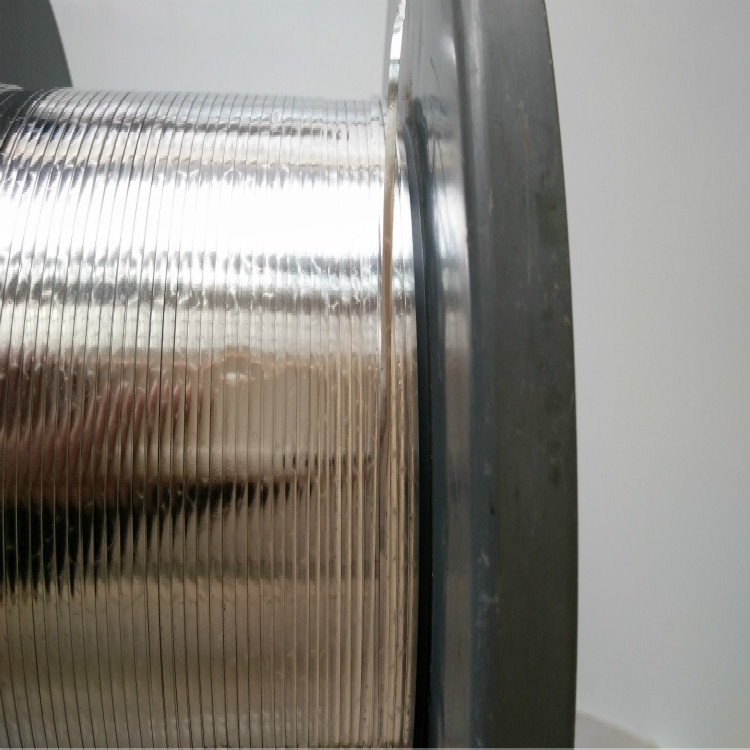

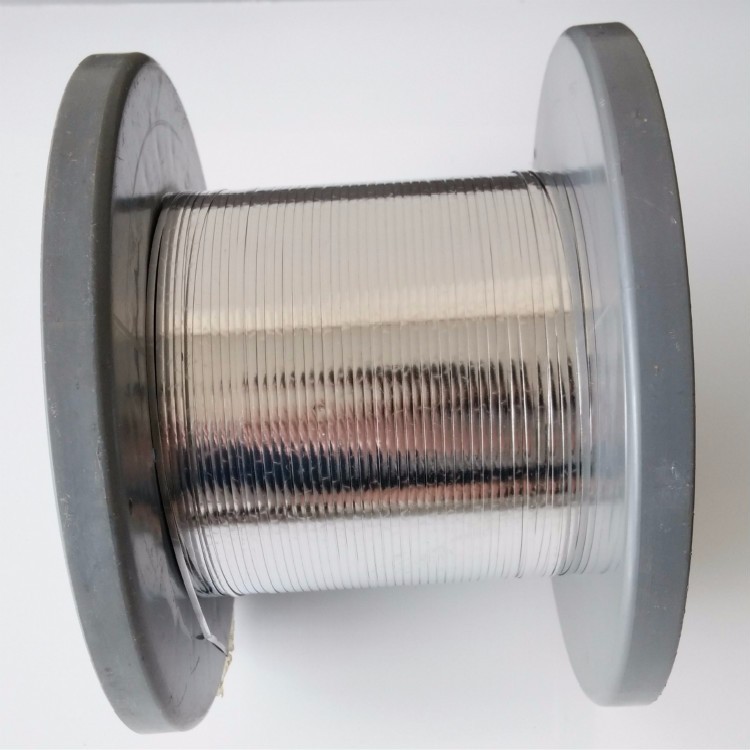

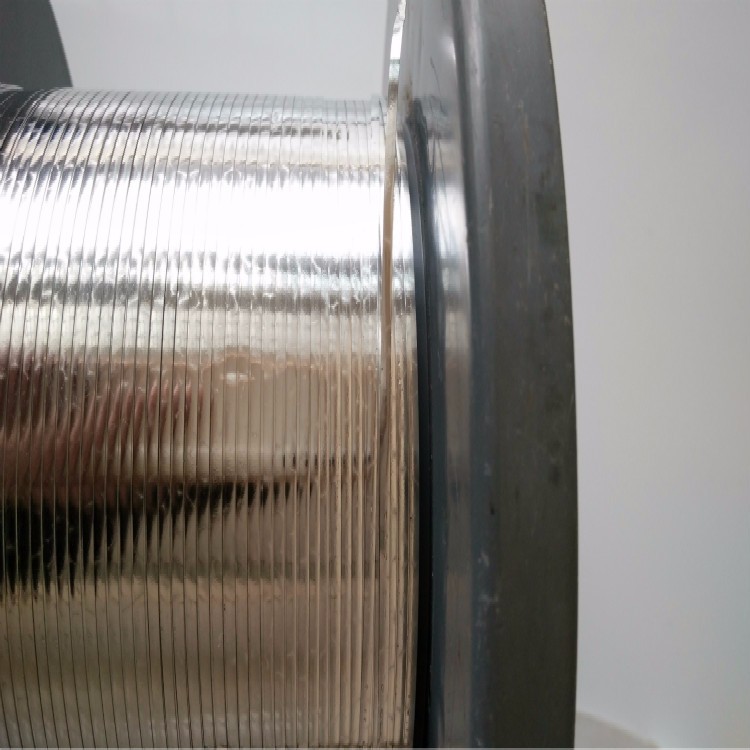

Spooling Packing Tabbing Hlau / PV Ribbon rau Tshuab Tsis Siv Neeg Soldering Hnub Ci Cell

Hnub ci interconnect ribbon yog ib hom zoo high-carbon steel hlau ntawm lub zog siab, siab hardness, thiab siab hnav tsis kam. Nws yog siv los ua tus cab kuj rau ntau cov hlau sawing los txiav cov ntaub ntawv nyuaj crystalline, xws li silicon, gallium arsenide, indium phosphide, silicon carbide thiab siv lead ua.

specifications

Hnub Ci Interconnet Ribbon General Introduciton

| 1. Base tooj liab Parameter | |

| Base tooj liab trademark | Oxygen-dawb tooj liab C1022 |

| Tooj purity | Cu≥99.97% |

| Hluav taws xob conductivity | ≥100% IACS |

| Kev tiv thaiv | ≤ 0.01724 Ω·m 2 / m |

| 2. Txheej Thickness thiab Composition (tuaj yeem kho raws li cov neeg siv khoom xav tau) | |||

| Txheej Alloy Hom | Txheej Txheej | Txheej Thickness ntawm txhua sab (mm) | Txheej Thickness kam rau ua (mm) |

| Coj | Sn60% Pb 40% | 0.01-0.04 Nws | ± 0.01 |

| Sn62% Pb36% Ag2% | 0.01-0.04 Nws | ± 0.01 | |

| Tsis muaj txhuas | Sn97% Ag3% | 0.01-0.04 Nws | ± 0.01 |

| 3. Mechanical Characters rau Commen Spool Khoom | |

| Elongation | ≥15% |

| Tensile zog | ≥150MPa |

| Sab camber | L≤8mm / 1000mm |

| 4. Lub cev Dimension thiab kam rau ua ntawm Common Spool khoom | |||

| Thickness ntau | 0.045-0.35mm (tuaj yeem kho raws li cov neeg siv khoom xav tau) | ||

| Thickness kam rau ua | ± 0.02 hli | ||

| Dav dav | 1.0-2.5mm (tuaj yeem kho raws li cov neeg siv khoom xav tau) | ||

| Dav kam rau ua | ± 0.08 hli | ||

| Common Specification ntawm Tabbing Ribbon (mm) (Spool Pob) | |||

| 0.18 × 2.0 hli | 0.22 × 2.0 hli | 0.24 × 2.0 hli | 0.27 × 2.0 hli |

| 0.20 × 1.5 hli | 0.23 × 1.5 hli | 0.25 × 1.5 hli | 0.30 × 1.5 hli |

| 0.20 × 1.6 hli | 0.23 × 1.6 hli | 0.25 × 1.6 hli | 0.30 × 1.6 hli |

| 0.2 × 1.8 hli | 0.23 × 1.8 hli | 0.25 × 1.8 hli | 0.30 × 1.8 hli |

| 0.2 × 2.0 hli | 0.23 × 2.0 hli | 0.25 × 2.0 hli | 0.30 × 2.0 hli |

Cia Tej yam kev mob thiab Txee lub neej

Tinned tooj liab ribbon yuav tsum tau muab cia rau hauv qhuav thiab ventilated chav tsev, qhov twg yuav tsum tsis muaj acid, alkail, los yog cov pa phem thiab cov av noo nyob rau hauv tsev yuav tsum tsis txhob ntau tshaj 60%. Muab nws horizontally thaum stacking thiab zam lub thawv extrusion & ntsug qhov chaw, lub caij no, stacking kom muaj nuj nqis ntawm tib yam khoom tsis pub tshaj tsib txheej lossis 1 tuj. Lub txee lub neej tuaj yeem mus txog rau lub hlis txij li hnub tsim khoom.

Khoom Qhia