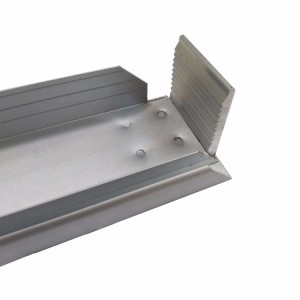

Hnub ci ribbon cell connector tsheb npav bar hlau

Kev piav qhia

Hnub ci Tabbing hlau Mechanical Property:

1. Elongation: E-Soft>= 20% U-Soft>= 15%

2. Tensile zog:> = 170MPa

3. Sab camber: L<=7mm/1000mm

4. Soldering tin melting point: 180 ~ 230 ° C

Electric Resistivity ntawm tooj liab:

TU1 <= 0.0618 Ω·mm2/m; T2 <= 0.01724 Ω·mm2/m

Core Copper ntawm TU1 Off-Cu lossis ETP1:

1. Copper Purity >= 99.97%, Oxygen <= 10ppm

2. Resistivity: ρ20 <= 0.017241 Ω·mm2 / m

Electric Resistivity ntawm Ribbon:

(2.1 ~ 2.5)X10-2 Ω·mm2 / m

Plated Thickness:

1) Tes-Soldering: 0.02-0.03mm ib sab

2) Tshuab-Soldering: 0.01-0.02mm ib sab

Muaj pes tsawg leeg ntawm Plated Khoom:

1) Cov khoom siv lead ua:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Cov khoom siv lead-dawb series:

A. Sn 96.5%, Ag 3.5% (Bi)

B. Sn 97%, Ag 3% thiab lwm yam

Txog Tabbing Ribbon & Bus bar Ribbon

PV ribbon yog tsim los ntawm tooj liab thiab txheej alloys, thiab muab faib ua Tabbing Ribbon thiab Bus bar ribbon.

1. Tabbing Ribbon

Tabbing Ribbon feem ntau txuas rau sab zoo thiab tsis zoo ntawm cov hlwb hauv koob.

2. Bus bar Ribbon

Bus bar Ribbon concentrates lub xov tooj ntawm tes rau hauv hlws ris lub thawv thiab raws cov hluav taws xob tam sim no.

Hais txog Coating Alloy:

Cov txheej txheej yog txiav txim los ntawm tus neeg siv khoom tsim thiab kev thov. Nws tau muab faib ua cov hmoov lead thiab tsis muaj hmoov txhuas. Tam sim no cov txheej txheej lead yog siv dav, tab sis yav tom ntej nws yuav raug tsim los rau hom tsis muaj hmoov txhuas.

specifications

| SIZE (mm) | Thickness (mm) | Khoom siv tooj liab | TSEEM CEEB | ||

| WXT | Base tooj liab | Lub tsho tiv no ib sab | Dav | Thickness | |

| 0.6 x 0.12 | 0.0500 Nws | 0.0150 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 0.8x 0 | 0.0500 Nws | 0.0150 Nws | TU 1 | ||

| 0.8 x 0.10 | 0.0500 Nws | 0.0250 Nws | TU 1 | ||

| 1.0 x 0.08 | 0.0500 Nws | 0.0150 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 1.0x 0.10 | 0.0500 Nws | 0.0250 Nws | TU 1 | ||

| 1.5 x 0.15 | 0.1000 Nws | 0.0250 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 1.5 x 0.20 | 0.1500 Nws | 0.0250 Nws | TU 1 | ||

| 1.6 x 0.15 | 0.1000 Nws | 0.0250 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 1.6 x 0.18 | 0.1250 Nws | 0.0275 ib | TU 1 | ||

| 1.6 x 0.20 | 0.1500 Nws | 0.0250 Nws | TU 1 | ||

| 1.8 x 0.15 | 0.1000 Nws | 0.0250 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 1.8 x 0.16 | 0.1100 Nws | 0.0250 Nws | TU 1 | ||

| 1.8 x 0.18 | 0.1250 Nws | 0.0275 ib | TU 1 | ||

| 1.8 x 0.20 | 0.1500 Nws | 0.0250 Nws | TU 1 | ||

| 2.0x 13 | 0.0800 Nws | 0.0250 Nws | TU 1 | +/- 0.05 | +/- 0.015 |

| 2.0x 15 | 0.1000 Nws | 0.0250 Nws | TU 1 | ||

| 2.0x 16 | 0.1100 Nws | 0.0250 Nws | TU 1 | ||

| 2.0x 18 | 0.1250 Nws | 0.0275 ib | TU 1 | ||

| 2.0x 20 | 0.1500 Nws | 0.0250 Nws | TU 1 | ||

Tshuab txheej txheem

1, Kev tsim cov kab sib txuas mus rau cov xov hlau tiaj tus los ntawm kev kos duab thiab dov

2, Kev kho cua sov

3, Kub-dip tinning

4, Precise spooling

Copper puag yog cov pa oxygen dawb tooj liab strips perssed los ntawm ultra-precision dov equipments mas los ntawm lub teb chaws Yelemees

Nws yog sleek thiab tsis muaj bur ntug, qhov muag hardness tuaj yeem hloov kho los ntawm cov neeg siv khoom xav tau.

Nrog rau cov txheej txheem tshwj xeeb, lub tsho tin alloy yog tsim los ntawm cov kws tshaj lij kub-dipping tinning equipments imported los ntawm Nyiv. Lub tsho tiv no yog ci thiab txawm, nws muaj peev xwm ua tau zoo thiab muaj zog antioxidant uas pab txhim kho qhov vuam tawm los. Nws cov thickness tuaj yeem hloov kho los ntawm cov neeg siv khoom xav tau.

Cov ribbon tuaj yeem ua rau xaj raws li hnub ci module thiab nws qhov ntev

Khoom Qhia